Bosch AppMini Project

December 27, 2017

A new generation of Bosch SensorTec Board for better testing and customer engagement. 90% reduction in size. 80% reduction in cost.

Important Notice: All the content of this project is the property of Robert Bosch LLC. This article only outline the working process and achievements, and reveal only publicly available data.

Background

I was in the Bosch SensorTec team during the internship. SensorTec team is responsible for pre-sale and post-sale technical support and consultancy. A critical tool we use is the Application Board and its corresponding Windows Application. Our engineers rely on it for testing and debugging purpose. And our customers reply on it to design, prototype and test our sensors, and eventually to determine whether the product(s) meet their needs.

Problem

As a legacy of MEMS manufacturing testing tool, the Application Board isn’t a particularly good fit for the daily work. Although powerful, but 80% of the features are only useful in manufacture calibration and tests, which accounts for the cumbersome software package and oversized hardware board. The shortcomings became more and more obvious as an increasing numbers of customers put their emphases on small IoT and wearable technologies. The size of the old board simply makes it hard to move around. Also, the software is not tailored to their specific needs.

Proposal

Trim off the inessential features from hardware and software level, create an easy-to-use board to promote sensor sales and bring convenience.

Results

Demo

OLD: Appplication Board & Application Desktop

NEW: AppMini & Web App

Form Factor Change Over Time

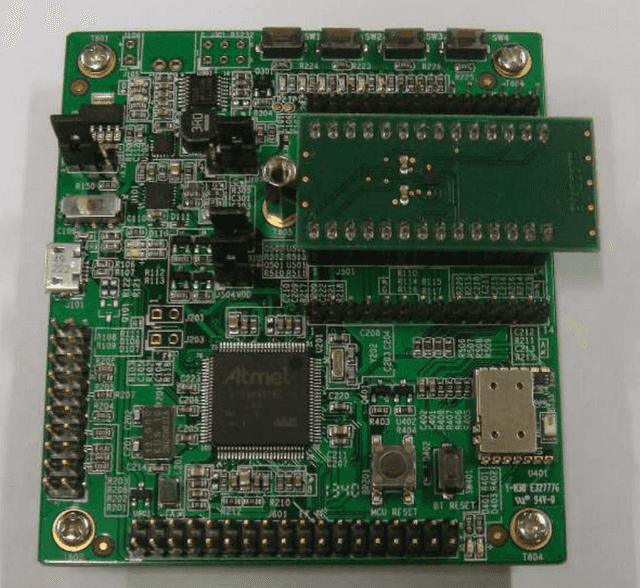

Old Test Board

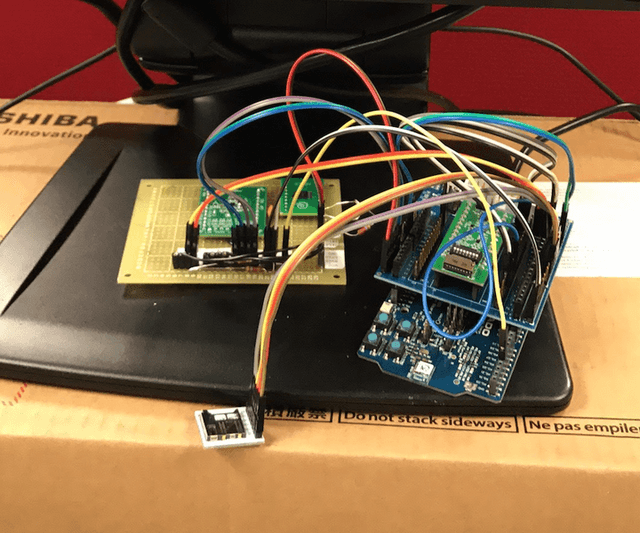

Resize Prototype

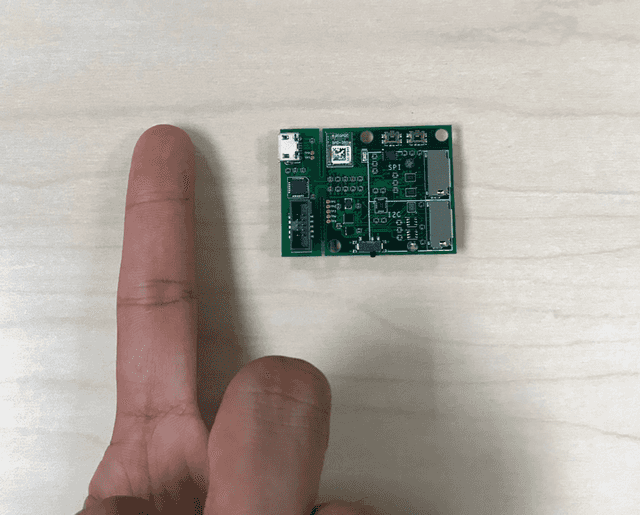

New Test Board

New Features

- new Nordic Soc: More Powerful and built-in Wireless Module

- new IOs: I2C, SPI, GPIO

- Multiple logging options

Achievements

Smaller Size Hardware: 75mmx83mm → 30mmx20mm : 91% reduction Lower Cost: 20: 80% reduction No Installation for Visualization & Logging App Cross-platform Potential to better engage customers(faster response and feedback time)

Limitation

Due to Webbluetooth availability, the Web App does not work on Windows without advanced configuration. However, it is changing, and will soon be suported officially.

© 2022 ruanjian.io